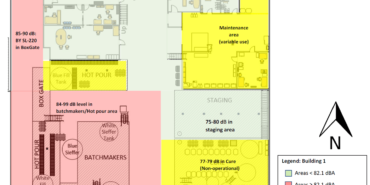

RHP Risk Management performed an industrial hygiene noise assessment, written hearing conservation program & chemical exposure sampling plan for a producer of asphalt products. RHP developed a site specific OSHA compliant written hearing conservation program.

- Client originally called for air testing. Upon arrival, RHP was told the company had recently been purchased and the new owner was requesting H&S would be brought up to compliance. RHP did complimentary walk-thru to identify workplace hazards (noise, chemical hazards, physical safety hazards).

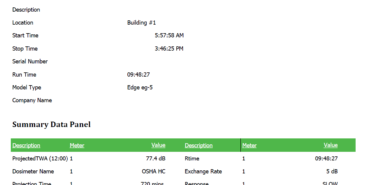

- RHP did employee monitoring exposure to noise and manufacturing processes (machinery & equipment) within 2 manufacturing buildings & large warehouse and used data logging noise dosimeters to measure full-shift (8-hour) individual employee noise exposures on employees. Noise monitoring was to determine the need for OSHA compliant hearing conservation program.

- RHP reviewed safety data sheets (incl. lists of chemicals) & determined what chemicals the employees were using in order to put together an IH exposure monitoring sampling plan & proposal.

- RHP evaluated noise dosimetry results and sound level meter readings, evaluated the effectiveness of the hearing protection of the hearing protection that was currently being provided to the employees. RHP determined written hearing conservation program & assisting with implementation.

- RHP developed a plan based upon the Employee Chemical Exposure Assessment completed based upon the chemical exposure sampling.

RHP Risk Management performed welding fume assessment, annual ventilation surveys & on-call EHS services. Employees wore personal breathing zone samplers and RHP performed full-shift air monitoring (approx. 12-hours) for metal associated with welding fumes.

- Samples were analyzed for 13 common metals associated with carbon steel welding. RHP provided detailed descriptions of work activities, PPE, and materials were reported.

- Using the guidelines of the “American Conference of Governmental Industrial Hygienists”, RHP performed an evaluation and testing of approx. 17 chemical hoods and local exhaust locations. RHP’s tests and procedures included smoke tube evaluations, cross-draft assessments, inspections for possible malfunctioning of airflow indicators, documented air velocity measurements and a final report with methods, results and recommendations.

RHP Risk Management was contacted by the client to conduct a limited asbestos inspection of an approximately 50′ x 100′ discontinued paint line structure that was being prepared for demolition. RHP was tasked with inspecting the line and collected samples of materials suspected to contain asbestos on the line and in the vicinity of the line to ensure asbestos-containing materials (ACMs) would not be disturbed during demolition activities. RHP collected a total of twenty (20) samples (boiler insulation, heat shield material, floor tiles, and mastic) from the mezzanine level area, the basement tool room and main office of the subject building.

- Samples were analyzed by the National Voluntary Laboratory Accreditation Program (NVLAP) laboratory for polarized light microscopy analysis. Further guidance was provided to the client regarding the asbestos abatement process. Following removal, RHP’s IDPH-licensed Air Sampling Professional conducted clearance air testing to ensure air quality within the contained work area was adequate for normal re-occupancy.

Client recently purchased the business and called RHP requesting their health & safety be brought up to compliance within 2 manufacturing buildings and warehouse. RHP Risk Management performed industrial hygiene exposure assessment at a facility that fabricates welded & woven wire mesh safety & security products, including pallet rack security systems, storage lockers and gas cylinder safety cabinets.

- RHP reviewed safety data sheets (including lists of chemicals used in the manufacturing process) and RHP determined what chemicals were being used & put together an industrial hygiene exposure monitoring sampling plan and proposal.

- RHP performed full-shift employee air monitoring during welding on carbon steel on 3 welders. Monitored employees wore a personal breathing zone sampler during the duration of their 8-hour work shift. Samples were analyzed for 13 common metals associated with carbon steel welding.

- RHP performed full-shift area air monitoring for respirable and/or total dust on 6 powder coat employees who wore a personal breathing zone sampler during the duration of the 8-hour work shift.

- RHP did noise monitoring to determine the need for OSHA compliant hearing conservation program. RHP determined written hearing conservation program and assisted with implementation.

- Upon completion of site activities and receipt of the laboratory analytical reports, RHP Risk Management provided a report that included presentation of findings and sampling results, comparison of the results with the applicable regulatory or best practice guidance, and conclusions and recommendations for further action.

A client with a 70,000 sq. ft. commercial space that included a shipping & receiving warehouse and 20,000 sq. ft. office area called RHP for an “incident response” project that involved worker complaints of illness from diesel exhaust or smoke that came from an unknown source from around the building. RHP assessed a full-profile of parameters of an entire day (morning, afternoon & evening), seeking areas containing a potential source of diesel exhaust (rooftop air handlers). The assessment consisted of particle counting including ultrafine particulate, and normal particulate monitoring using a direct-reading particulate meter, a multi-RAE ‘PID’ gas meter to analyze organic compounds; CO, CO2, NO2 & SO2 sensors, combustion byproducts (from diesel engines, fork lifts or fires), and carbon monoxide sensors.

- RHP determined the employee complaints were unique scenarios caused by the location and orientation of the air handlers located on the facility’s roof, and any of the measured contaminants may have spiked if outdoor conditions aligned (train or idling semi coupled with a strong wind).

- RHP made recommendations that all areas that needed sealed between the warehouse and employee work spaces were inspected, re-sealed, building ventilation cleaned, and addition of local exhaust at the shipping dock.

In response to resident’s health & safety concerns, RHP was hired to develop & conduct an air quality study surrounding a municipal waste transfer station to determine if the facility was contributing to increased pollution within the surrounding community (approx. 1.5 mile radius). RHP developed a comprehensive air monitoring network consisting of 5 solar-powered stations that were each equipped to measure air quality parameters such as vapors, particulate matter & noise.

- RHP hosted community meetings throughout the 6-month evaluation period.

- Developed a website dedicated specifically for the project & updated weekly with found data.

- Compiled, analyzed and presented project results to stakeholders with recommendations for future studies.

Client was a general contractor during conversion of a high-rise building and contacted RHP to ensure their safety protocols were working properly. RHP conducted bi-weekly safety walk-throughs, provided on-site health & safety auditing and support. RHP provided a report listing any findings with corrective measures, held safety meetings and was available for on-call health & safety support related to specific issues.

RHP Risk Management was contacted by a community park district for a pre-demolition inspection of a vacant commercial property that included a main building, a secondary aluminum structure and a garage structure with an attached office. RHP responded with an Illinois Department of Public Health (IDPH) asbestos building inspector who collected samples of suspect building materials according to the guidelines generally outlined in 40 CFR Part 763.

- RHP performed an asbestos inspection of all three structure and collected suspect asbestos-containing building materials: pipe insulation, elbow insulation, floor tiles, sealants, glazing, caulk, roof flashing, and drywall. To obtain roof core samples, RHP cut into the roof down to the plywood deck.

- The suspected materials were taken to a National Voluntary Laboratory Accreditation Program (NVLAP) laboratory for polarized light microscopy analysis. RHP provided a summary report, laboratory report and necessary documentation for client to obtain demolition permit. Further guidance was provided to the client regarding the asbestos abatement process. Following removal, RHP’s IDPH-licensed Air Sampling Professional conducted clearance air testing to ensure air quality within the contained work area was adequate for normal re-occupancy.

A manufacturer and installer of stone and composite products operates a 30,000 square foot facility with 24 employees who manufacture and install its products. The client asked RHP to evaluate employee exposures and make recommendations to achieve compliance with OSHA’s revised crystalline silica regulation for general industry that went into effect on June 23, 2018.

RHP performed air sampling, evaluated work practices and engineering controls, and assessed personal protective equipment.

What We Found

- Plant Operations Employees – 7 of the 12 air sample results exceeded the OSHA Action Level.

- Off-Site Installers – All air sampling results were below the OSHA Action Level.

What We Recommended

Plant Operations Employees:

- Employee Notification – Notify affected employees of the sampling results within 15 working days.

- Written Respiratory Protection Program – Until additional exposure sampling confirms that engineering and work practice controls have successfully reduced employee exposures, prepare a written respiratory protection program in accordance with 29 CFR 1910.134 Respiratory Protection.

- Housekeeping – Unless deemed infeasible, do not perform:

- dry brushing or sweeping, unless wet sweeping and HEPA-filtered vacuuming are infeasible; and

- cleaning of surfaces or clothing with compressed air, unless compressed air is used in conjunction with ventilation that effectively captures the dust.

- Grinding and Shaping Using Pneumatic Hand Tool Use – Consider the following:

- isolate and provide local exhaust ventilation and wet methods for the grinding and shaping table area.

- Written Exposure Control Plan – Prepare a written exposure control plan in accordance with 29 CFR 1910.1053 Respirable Crystalline Silica.

- Repeat Sampling – Within 3 months.

Off-Site Installers:

- Voluntary Use of Filtering Facepieces (Dust Masks) – Employers must comply with the requirements of OSHA’s Respiratory Protection Standard regarding voluntary respirator use.

- Change of Process, Materials, or Conditions – If the off-site installation process, equipment or conditions change such that dust is confined or incapable of being dispersed, additional exposure monitoring must be performed to determine exposures under these changed conditions.

Update – 3 months later

- Once RHP’s recommendations were implemented, the company called us to repeat the assessment. Our assessment was coordinated to correspond to the 3-month repeat exposure sampling deadline required by OSHA when exposure exposures exceed the Permissible Exposure Limit.

- Plant Manufacturing Operations – The company implemented all our recommendations and all repeat air sampling results were well below the OSHA Action Level.