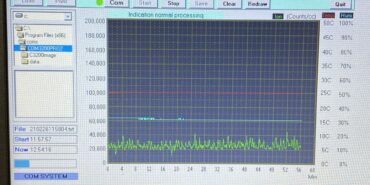

As the pandemic progressed, an increasing recognition evolved about the role of aerosol transmission and technologies to improve indoor air quality through building ventilation. There are many ways to improve indoor air quality and reduce the risk of viral transmission using existing and proven technologies like air filtration and introducing more outside air. The problem is that these approaches have an energy penalty and cost building operators more money. Thus, the attraction of many new-to-market air purifier devices, or as the CDC calls them “emerging technologies”, such as needlepoint bi-polar ionization (NPBI). To understand if NPBI technology claims translates to real-world as-installed environments in occupied buildings, RHP conducted an internal research study aimed at investigating and replicating installation and performance of an NBPI device.

Adenosine Triphosphate (ATP) bioluminescence, an indirect measurement of the amount of organic residue on a surface (live or dead), has been commonly used to evaluate cleanliness of food preparation surfaces for more than forty years and research has shown it is effective in addressing cleanliness in other environments such as schools and office settings.

ATP is an energy molecule found in plant and animal microbiol cells including food, bacteria, mold and other microorganisms. ATP is measured in relative light units (RLU) which is the measurement of light emitted from a reaction between ATP and swap reagent. Viruses such as SARS-CoV-2 cannot generate or store energy in the form of ATP and ATP surface testing does not measure viruses; however, ATP measurements can be useful for evaluating the effectiveness of hygiene interventions aimed at preventing viral spread in the workplace. RT-qPCR (Reverse Transcription, quantitative-Polymerase Chain Reaction) is a technique used to measure viral RNA and can test for the presence of SARS-CoV-2 on environmental surface samples.

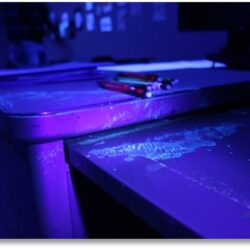

In order to visualize and assess cleaning procedures as compared to normal background levels measured in various settings, three simulated sneeze scenarios were conducted in a simulated classroom setting, each followed by a different cleaning procedure (occupant (teacher), routine janitorial, and hired professional). Each sneeze was comprised of viscus liquid containing both fluorescent dye and surrogate pathogen and each scenario assumed an infectious disease plan was in place but without management oversite.

ASTM’s personal protective clothing and equipment committee developed the ASTM F3407-20 and F3407-21 Standard Test Method for Respirator Fit Capability for Negative-Pressure Half-Facepiece Particulate Respirators (RFC Standard).

The ASTM Standards F3407-20 and F3407-21 provides increased assurance to respirator purchasers and users that respirators that meet the requirement of this standard can be expected to effectively fit persons with various length and widths of faces, such as long and narrow or short and wide, when fit tested as part of a complete respiratory protection program in accordance with 29 CFR 1910.134.