(866) 481-8188

Call to Speak with a Specialist

Workers in the natural cut stone industry including finishing and installing both natural and manufactured stone may be at an increased risk of exposure to silica. In manufacturing and fabrication shops operators, cutters and polishers, inspectors, quality control technicians, as well as workers who perform maintenance and housekeeping activities in manufacturing and fabrication facilities may be at an increased risk to hazardous levels of airborne silica-containing dust.

Crystalline silica occurs in nature as a component of granite, sandstone, quartzite, and sand. Work activities with natural stone involves different initial steps than working with manufactured stone. Granite and other natural stones are quarried and cut into large stone slabs increasing a risk of exposure to crystalline silica dust. The slabs are further cut into countertop sizes at the quarries or at stone finishing shops. Manufactured stone countertop production includes the making of engineered or cultured slabs, that entails the mixing of crystalline silica, resins, and pigments.

The Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) have identified exposure to silica as a health hazard to work forces involved in manufacturing, fabricating, finishing and installing natural and manufactured stone countertop products concerns have been raised for both fabrication shops and on-site finishing/installation, and onsite liabilities may also include building occupants and homeowners if present. Under the OSH Act of 1970, employers are responsible for providing safe and healthful working conditions for their workers. The OSHA respirable crystalline silica standard for the construction industry (1926.1153) and the OSHA respirable crystalline silica standard for the general industry and maritime (1910.1053) require employers to perform air monitoring to determine the volume of silica that workers may be exposed to. Further these standards work to protect workers from respirable crystalline silica exposures above the permissible exposure limit, provide requirements for workers to be provided respiratory protection, and implementation of a variety of administrative controls.

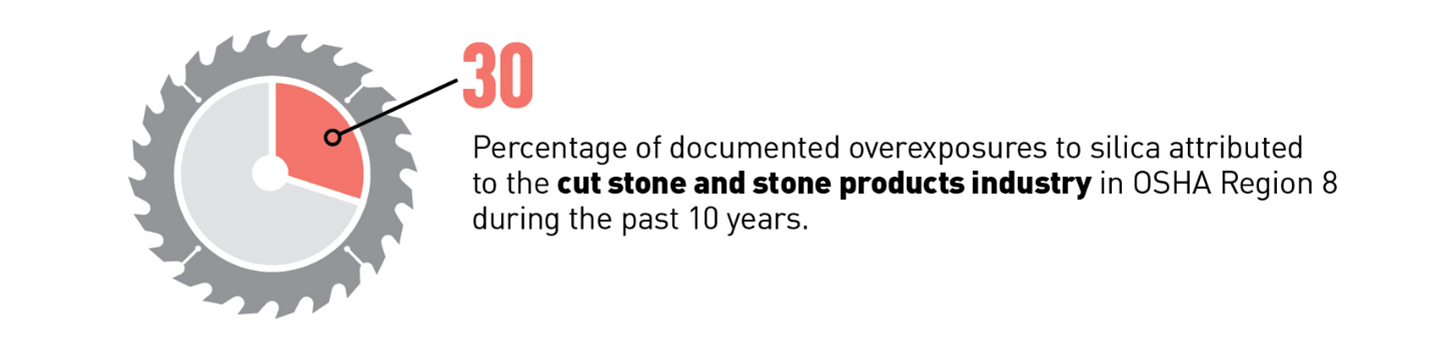

A Regional Emphasis Program (REP) developed by OSHA is intended to identify and reduce respirable crystalline silica hazards in the cut stone and stone products industry in Region 8 covering Colorado, Montana, North Dakota, South Dakota, Utah, and Wyoming. According to OSHA, the cut stone and stone products industry has had the highest documented overexposures to respirable crystalline silica in region 8 in recent years. Enforcement under the REP began in May 2022.

What Concerns Should Employers in the Stone Countertop Manufacturing, Finishing and Installation Industry Be Aware Of?

Workers in the countertop manufacturing, finishing and installation industries may be at risk for exposure to silica dust during the operation of powered saws, grinders, and high-speed polishers on natural and manufactured stone. Exposures can occur during dry cutting, grinding, edging, polishing and contouring stone, and may in shop environments as well as on job sites where finishing work is often completed. Working with ground quartz during the countertop manufacturing industry may also lead to worker exposures to silica dust.

The silica/quartz content of common natural and engineered stones vary among stone varieties. Depending on the type of stone in question, the countertops being fabricated may contain over 90% silica. The highest silica levels are typically associated with manufactured countertops, where pigments and adhesives comprise the remaining materials. Silica is generally lower in natural stone products (granite, sandstone, quartzite), however granite may contain up to 45% silica.

The NIOSH Recommended Exposure Limit (REL) recommends that employers control exposure to respirable crystalline silica to prevent workers from exposure risks above a time-weighted average concentration of silica greater than 50 μg/m3 of air, as determined by a full-shift sample for up to a 10-hour workday of a 40-hour workweek. The OSHA Permissible Exposure Limit (PEL) states employers shall ensure that workers are not exposed to an airborne concentration of respirable crystalline silica in excess of 50 μg/m3, calculated as an 8-hour TWA. The OSHA standards states that employers shall assess the exposure of each employee who is or may reasonably be expected to be exposed to respirable crystalline silica at or above the action level (AL) of 25 μg/m3, calculated as an 8-hour TWA.

What Can Be Done at Your Worksite?

RHP Risk Management professionals perform respirable crystalline silica assessments to measure and collect data. For the stone countertop manufacturing, finishing and installation industry, measuring and quantifying worker and workplace exposures of airborne concentrations of respirable crystalline silica in the breathing zone can mean the difference between compliance and citations.

Upon analysis of the results, RHP experts work with employers to select NIOSH-approved respiratory protection for their workplaces, identify areas where workers may be at risk of exposure above occupational exposure limits, implement workplace practices and engineering controls (e.g., water sprays to control dusts, ventilation controls, and HEPA filters) to minimize dust generation in areas of concern, and establish and implement a written exposure control plan or update an existing plan to identify tasks involving silica exposures and methods used to protect workers.

Protecting Your Workers

OSHA standards require employers to measure the amount of silica that workers are exposed to; protect workers from respirable crystalline silica exposures above the PEL; limit access to areas where workers could be exposed above the PEL; use dust controls and safe work methods; provide respirators to workers when dust controls and safer work methods cannot limit exposures to the PEL; establish and implement a written exposure control plan; offer medical exams that includes chest X-rays and lung function tests every 3 years to workers exposed at or above the action level for 30 or more days per year; train workers; and keep records of workers’ silica exposure and medical exams.

To help reduce silica dust levels in the air, whenever possible, during cutting, grinding and shaping of natural and manufactured stone should be done under wet conditions and with ventilation and filtration systems to collect silica-containing dust at its source. Following a review of possible engineering and administrative controls, RHP’s occupational health and safety professionals perform respirator fit testing for employers looking to provide their employees the correct PPE and fit to protect their workforce from respiratory hazards within the stone countertop manufacturing, finishing and installation industry.

How Can RHP Help You?

RHP Risk Management’s Certified Industrial Hygienists (CIH), public health scientists and Certified Safety Professionals (CSP) are well versed and knowledgeable in navigating clients through the OSHA silica regulations and exposure limits, silica testing and air sampling for silica, identifying and mitigating worker exposures to crystalline silica, and by recommending and implementing controls that are effective, efficient, and economically feasible. Contact RHP Risk Management to learn more about our silica consulting services.