(866) 481-8188

Call to Speak with a Specialist

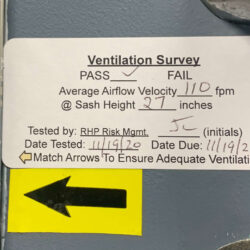

The laboratory fume hood is a ventilated enclosure used to contain and vent gases, vapors, and fumes separately from the building’s HVAC system. Following regulatory safety guidelines for fume hoods is important for protecting laboratory professionals from air contaminants and flammable or hazardous chemicals. RHP Risk Management’s EH&S professionals perform functional performance testing of chemical fume hoods at hospitals, laboratories, and educational facilities. Additionally, owners should establish a program to have their laboratory fume hood tested and certified regularly.

How Frequently Should a Fume Hood Be Inspected?

According to the OSHA Occupational Exposure to Hazardous Chemicals in Laboratories standard (29 CFR 1910.1450), chemical fume hoods should be certified annually and re-evaluations should be performed any time changes are made to the equipment. Additionally, new fume hoods should be tested upon installation prior to utilization. Certain state programs may have enhanced requirements.

For optimal laboratory safety workers should practice daily checks that include a visual inspection to ensure there are no blockages that may restrict air flow. This helps to ensure a safe work environment and proper fume hood operation. Additional precautionary measures can be taken such as installing a visual airflow alarm to indicate whether the fume hood is safe to operate.

Why Should You Have A Fume Hood Inspection Annually?

Fume hood testing certification will keep your laboratory OSHA compliant and provide a safe work environment for employees by containing and removing vapors, dusts, gases, and fumes generated within the hood. Annual fume hood certification and testing can identify problems with the hood’s ventilation system’s baffles, fans, and ductwork.

Employers may develop a laboratory fume hood inspection and certification program based on OSHA regulations (Standard 29 CFR 1910.1450) and the AIHA Laboratory Ventilation (ANSI/AIHA Standard Z9.5) to ensure proper fume hood operation. The inspection and certification program may include allowable average and maximum exposure levels, allowable fume hood face velocities, and required speed of response for variable volume operations.

What’s Included in RHP’s Fume Hood Testing Procedure?

RHP’s EH&S professionals administer functional performance testing of fume hoods according to the methods described in ANSI/AIHA Z9.5. This method is designed to assess hood effectiveness and confirm that laboratory ventilation equipment is calibrated to flow at regulatory, method, and containment specific airflow rates.

ASHRAE Standard 110 is a quantitative test procedure for determining the operating capabilities of a fume hood. ASHRAE 110 identifies three test types, As Manufactured (AM), As Installed (AI) and As Used (AU):

- As Manufactured (AM): is done once the hood is built and done in a testing lab where as many environmental factors are removed as possible.

- As Installed (AI): testing is done once the hood is installed in the lab but before anything is placed inside.

- As Used (AU): testing is done in the lab with materials (beakers, equipment, etc.) inside the hood. This test takes into account both the room environment and users, and can determine if there is an issue with how it is being operated by comparing the test results to the AI results. The AU test should be conducted annually.

Test the Performance of Your Fume Hood with RHP Risk Management

RHP Risk Management’s Industrial Hygienists and Certified Occupational Health & Safety Professionals work closely with hospitals, laboratories, and educational facilities for functional performance testing of fume hoods and development of fume hood inspection and certification programs. We provide solutions that meet OSHA compliance that are effective, achievable, and manageable. Contact RHP by calling (773) 867-6010.