Call to Speak with a Specialist

Workers, whether indoor or outdoor, who work in environments or climates that expose them to extreme heat may be at risk of heat stress. Heat stress may result in heat rashes, heat cramps, heat exhaustion, or heat stroke.

Examples of workers at risk of heat stress include outdoor workers in hot environments such as firefighters, farmers, construction workers, and miners, and examples of indoor workers such as boiler room and factory workers.

Workers at greater risk of heat stress include those who are 65 years of age or older, or are overweight, have heart disease or high blood pressure, or take medications that may be affected by extreme heat.

What are Heat Stress and Heat Strain?

Heat Stress is defined by the net heat load to which a worker may be exposed from the combined contributions of environmental and metabolic factors (i.e., air temperature, humidity, air movement, and radiant heat), and clothing requirements. Heat Strain occurs when the body cannot rid itself of excess heat. Illnesses related to heat stress can include heat stroke, heat exhaustion, rhabdomyolysis, dizziness, cramps, and rash. Hydration and rest are important for heat stroke prevention, but the most effective way to prevent heat stroke in an occupational setting is to implement work practice controls. The Centers for Disease Control and Prevention (CDC) guidance provides recommendations on control measures for heat stress prevention by implementing engineering and work practice controls.

To reduce workplace heat stress, employers may use engineering and administrative (work practice) controls and provide training to workers to better understand the dangers of heat stress, how it affects their health and safety, and how it can be prevented.

Prevention Strategies to Reduce Heat Stress in the workplace: Engineering Controls, Employee Training, Acclimatization, Hydration, and Rest Breaks.

Engineering Controls and Work Practices to Reduce Risk of Employee Heat Stress

Engineering controls that cool the work environment or reduce manual workload with mechanization may be effective in the prevention of heat stress and heat-related illnesses. Engineering controls may include: air conditioning (including air-conditioned construction equipment cabs, and air-conditioned break rooms), general building ventilation, cooling fans and misting fans, local exhaust ventilation at points of high-heat production or moisture, use of reflective shields or barriers to redirect radiant heat, insulation of hot surfaces (furnace walls), elimination of steam leaks, and use of mechanical equipment to reduce manual work (conveyors and forklifts).

Work practices and administrative controls to improve heat stress safety include modification of work schedules and activities to help limit time in heat and increase time spent in a recovery environment, reduce physical demands as much as possible by planning the work to minimize manual effort (delivering material to the point of use so that manual handling is minimized), rotate job functions among workers to help minimize exertion and heat exposure, ensure workers drink and adequate amount of water or electrolyte-containing fluids, and have an emergency plan that specifies what to do if a worker shows signs of heat stress or heat-related illness, and ensures that medical services are available if needed.

From a Risk Management Perspective, What Steps Can a Business Take to Reduce Risk for Heat Stress and Heat Illness in the Workplace? – excerpt from Rod Harvey, P.E., CIH, CSP, CHMM interview with Business Insurance

Employee Training for Heat Stress and Heat Strain

By providing a heat stress safety training program for workers in both indoor and outdoor conditions during hot months employers give their workforce the tools to recognize and mitigate risks. Tailored training to the worksite-specific conditions of each task or job to better help employees learn to recognize the signs and symptoms of heat strain / heat-related illness and feel comfortable with halting work if necessary. Supervisors trained in hot weather advisories and emergency response procedures due to heat stress will know when and how to respond. Supervisors should encourage adequate fluid intake and rest breaks.

Heat Acclimatization for Workers

An important aspect of heat stress prevention is acclimatization to better help the body gradually build a tolerance to heat over time. The CDC defines acclimatization as the result of beneficial physiological adaptations, such as increased sweating efficiency, that occur following repeated exposure to a hot environment. If workers are exposed to a new environment that is subject to high heat or if employing recently hired or transplanted workers that are new to working in warm environments, a heat acclimatization plan can reduce the risk of heat stress for workers that are exposed to a new environment that may be subject to high heat.

Hydration

Drinking enough fluids is one of the most important tools you can use to prevent heat illness of your workers. Water is generally sufficient for hydration, as long as regular meals are eaten to replace salt lost in sweat. According to a National Institute for Occupational Safety and Health (NIOSH) heat stress fact sheet, the key to hydration is to drink water before one becomes thirsty.

Hydration before work, during work in hot conditions, and after work is imperative to increase hydration and prevent heat illness. NIOSH recommends employees who are working in hot environments to monitor the color of their urine throughout the day to gauge their level of hydration, and employers provide a proper supply of water that is maintained throughout the workday and allow workers to hydrate themselves during exposure to high heat.

Rest Breaks

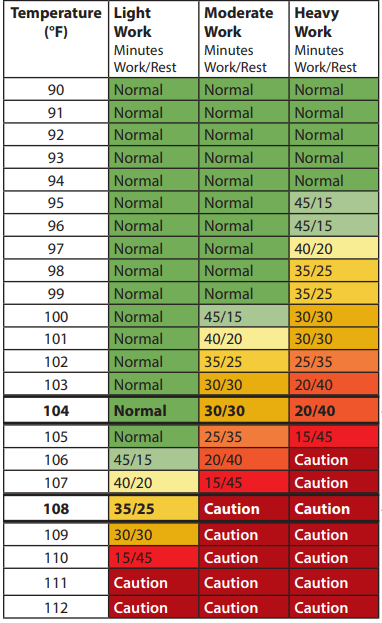

According to NIOSH, workers need to take breaks when exposed to hot temperature environments that last long enough for workers to recover from the heat. The length of time depends on several factors, including the WetBulb Globe Temperature (WBGT) measurement of the heat stress in direct sunlight, which takes into account temperature, humidity, wind speed, sun angle and cloud cover (solar radiation).

Short break periods will split longer work hours into smaller chunks and allow workers to recharge and operate more efficiently. Rest periods should be increased if temperature or humidity increase, there is no air movement, protective clothing or equipment is worn, or for “heavier work”. According to NIOSH, in extreme cases of heat stress or high temperatures, even a work/rest schedule may not eliminate the risk of heat stroke of heat illness. NIOSH does not advise continuous work in heat.

Contact RHP Risk Management to Reduce the Risk of Heat Stress in Your Workplace

RHP Risk Management’s staff of experienced Industrial Hygienists provide guidance to employers implementing occupational health and safety plans.

For more on RHP’s expertise in heat stress, watch Rod Harvey’s, P.E., CIH, CSP, CHMM interview with Business Insurance on how heat events can elevate property and liability risks and risk management steps can be taken to mitigate heat events; listen to Rod’s discussion on the Missouri Employers Mutual podcast about the warning signs of heat stress, employee training, and solutions to working in hot conditions; and listen to Rod’s appearance on the Greenberg Traurig podcast to discuss OSHA’s National Emphasis Program related to heat hazards, effective employer prevention strategies, controls, training and occupational heat stress litigation.

Contact RHP for an initial consultation or call (773) 867-6010.

Learn More About Heat Stress:

![]() Heat Stress: The Hidden Hazard That Comes with Warming Weather

Heat Stress: The Hidden Hazard That Comes with Warming Weather

RHP’s Rod Harvey, P.E., CIH, CSP, CHMM joined host Heather Carl on the Missouri Employers Mutual workSAFE podcast and discussed the warning signs of heat stress, how employers can equip employees to handle high temperatures throughout the day, and share short-and long-term solutions to working in hot conditions.

Click to listen to “Heat Stress: The Hidden Hazard That Comes with Warming Weather”

Heat Hazards in the Workplace and OSHA – Workplace Safety Review Podcast

Heat Hazards in the Workplace and OSHA – Workplace Safety Review Podcast

RHP’s Rod Harvey, P.E., CIH, CSP, CHMM was a guest on the Workplace Safety Review podcast where he was interviewed by Michael T. Taylor and Adam Roseman of Greenberg Traurig on OSHA’s National Emphasis Program related to heat hazards, effective employer prevention strategies, controls, training and occupational heat stress litigation.

Click to listen to “Heat Hazards in the Workplace and OSHA” podcast