Understanding exposure to hazards that pose a potential health risk to workers is important for employers to appropriately eliminate, control, and reduce risk to keep workers safe. With help from a Certified Industrial Hygienist or industrial hygiene professional, an occupational risk assessment can help employers address and mitigate their most critical workplace safety hazards by implementing the necessary procedures and control measures.

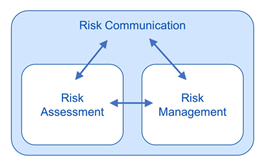

A risk assessment is a key component to a risk analysis. A risk assessment identifies the hazard. Risk management puts policies in place and manages decisions of risk. Ultimately, risk communication involves exchange of information involving the risk in question. This interconnected process of risk analysis is ongoing and updated when necessary.

What is risk assessment?

A risk assessment is a systematic process involving the identification, analysis, and control of hazards. Risk is determined by evaluating the likelihood that somebody may be harmed by a given hazard and the severity of the hazard. The assessment is performed to determine what measures should be enacted to best eliminate or control the workplace risk.

Identifying hazards is an important element when ensuring the health and safety of employees in the workplace. To ensure compliance with regulatory requirements, employers are responsible to perform risk assessments when new processes or steps are introduced to the work environment, changes are made to existing processes, or new equipment, tools, and/or hazards enter the workplace.

The goal of a risk assessment is to evaluate and remove the hazard completely or minimize the level of risk to employees by adding control measures with the goal of a safer and healthier workplace.

5 Steps of a Risk Assessment

- Identify hazards

- Evaluate the risks

- Decide on control measure to implement

- Document the findings

- Review the assessment and update if necessary

Types of Risk Assessment

Risk assessments can be divided into two main groups: quantitative and qualitative. Quantitative assessments involve information gathered and expressed numerically, while qualitative assessments involve gathering data by observation which is expressed on a scale.

Quantitative risk assessments can be extremely informative as they provide exposure information from known or estimated values for workplace parameters. Examples of quantitative risk assessments include the use of tools such as the NIOSH Lifting Equation or exposure modeling software. Modeling software can be particularly advantageous when performing risk assessments of product use. Software exposure modeling can be performed with a tiered approach to fit the unique needs of individual clients and exposure scenarios. For example, tier one modeling can inform on worst case scenario exposures using conservative values. Tier two modeling can report on exposure scenarios based on more informed estimates of specified parameters that are more reflective of a product use scenario. Finally, the most sophisticated form of modeling is tier three modeling, which informs on the actual product use scenario, with known parameter values for the model. Tier three modeling is the most robust type of modeling, and also the most comprehensive model.

Generic risk assessments address common hazards for a work task or process and can be used for similar activities or equipment across different sites, departments, or companies. A site-specific risk assessment is completed for a specific aspect of work and considers the site location, environmental factors, and workers performing the work. A dynamic risk assessment is performed for an “on the spot” situation and is used to manage unknown risks and uncertainty.

Control Measures

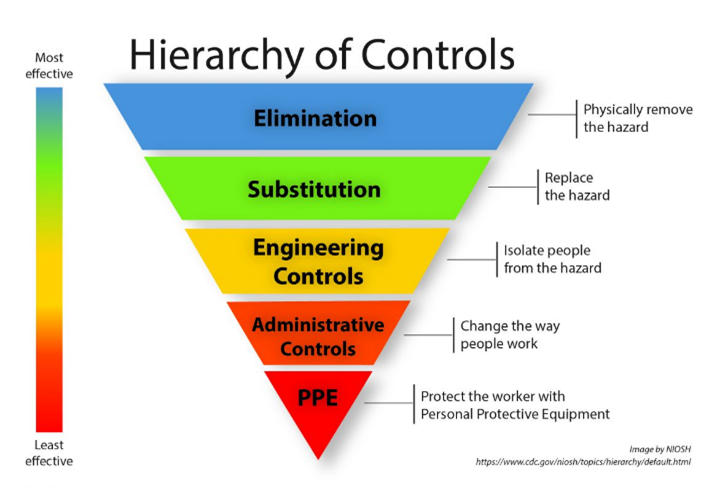

Once a hazard is identified, a decision can be made for what control method is best to implement. Hazard control methods include elimination, substitution, engineering controls, administrative controls, or personal protective equipment. The Hierarchy of Controls lists these types of hazard control methods from most effective measures to least effective measures. Elimination of the hazard is the most effective option.

Why are risk assessments important?

Risk assessments are an essential part of an occupational health and safety management plan that help to create awareness of hazards and risks; identify who may be at risk; determine whether a control program is required for a particular hazard; determine if existing control measures are adequate or if the measures need to be updated; prevent injuries and illnesses; prioritize hazards and control measures; and meet legal requirements where applicable.

How do noise levels impact workplace safety?

Understanding exposure to hazards, like excessive noise, is crucial for employers to protect worker health and safety. Risk assessments help identify and control these hazards, ensuring compliance under OSHA regulations and preventing injuries. By implementing necessary procedures and administrative controls, employers can mitigate risks associated with noise and create a safer, healthier workplace.

Contact RHP for an initial consultation or call (773) 867-6010.